In this day and age, prompt service is demanded by all industries, as businesses now consider speed to be a critical component of success. The idea of quick prototyping is in demand in the market in this regard. China has become one of the emerging countries where you can find several rapid prototype manufacturers.

Because of the availability of large numbers of high-skilled technical persons in China, this service is available at a very low price, which is also helping the country’s booming economy a lot. Today, China has achieved a leadership position in developing rapid prototypes.

Prioritizing quality above everything else is crucial while searching for a service provider to design your prototype. This post will cover all there is to know about rapid prototyping, including how to choose the best Chinese makers of rapid prototypes.

What is a prototype?

First, let us attempt to define what a prototype is. When developing a new product, the first step is to make a sample model that you can use to explain the concept to potential customers. In this prototype model, you can experience all kinds of problems with your proposed product and its solutions, too.

The prototype offers you the opportunity to know what design changes are necessary for your proposed product so that it can meet the requirements of your target customers. This model is very useful for you to analyse any problems that you may face in your product in the future too. You will know which area of the product design you should pay more attention to.

What is rapid prototyping?

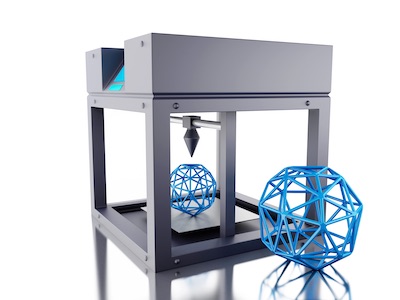

Now, let us understand rapid prototyping. This is a technique to develop the physical model quickly in a three-dimensional way so that you can decide how your model will look and what parts are needed for it. All these will be designed by Computer-Aided Design, which is also known as CAD.

Through CAD, you will be able to get all possible data about the dimensions of your model and also its various parts. You can validate the design of your product faster with CAD design, and hence, it is known as rapid prototyping.

To create an actual model of a rapid prototype, usually, the following methods are employed:

- Injection moulding

- CNC machining

- 3D printing.

China’s rapid prototype manufacturing

China has plenty of qualified engineers, and hence, it has developed a good market for rapid prototyping. Globally, China is now recognized as a powerhouse for rapid prototyping.

Chinese rapid prototype manufacturers vary in size from major, well-known organizations to smaller, niche businesses. A few prominent companies in China provide end-to-end services for various prototype techniques, serving markets including:

- Consumer electronics

- Medical devices

- Automotive

- Aerospace.

All rapid Chinese prototype manufacturers provide comprehensive services spanning many prototype methodologies. Here is a detailed look at the key features of rapid prototyping in China:

1. Types of rapid prototyping technologies

a. 3D printing

A digital model of the prototype is developed through CAD in the beginning as explained above, and 3-dimensional printing are implemented, which offers details of the prototype. This technique has become quite popular because it allows for the development of exact designs quickly without wasting any material.

A typical 3D printing technology will consist of the following:

- Fused Deposition Modelling (FDM): Fused deposition modelling is an additive manufacturing technology that creates 3D components using a continuous thermoplastic or composite material thread in filament form. An extruder feeds the plastic filament through an extruding nozzle, which is melted and then selectively deposited layer by layer onto the build platform in a predetermined automated path.

- Stereolithography (SLA): SLA technology is also becoming a popular option in China. In this technique, your rapid prototype service provider will use certain liquid resins, which are cured by ultraviolet light.

- Selective Laser Sintering (SLS): Another latest technique that has evolved in the market is SLS technology, where the laser will be used for sintering powdered material to create a robust prototype.

b. CNC machining

The process of using certain machinery, which is totally computer-controlled, for shaping and cutting various materials to create the shape of your prototype model is called CNC machining. You can use this method to create your prototype by using many different materials of your choice. CNC machining will create an accurate prototype model.

c. Injection moulding

Another method employed for creating a prototype is called injection moulding. Here, your desired material will be injected in a molten form to create the shape of your prototype. It is renowned for being effective and for producing items with superior surface finishes and high strengths.

2. Advantages of choosing Chinese manufacturers

a. Cost-effectiveness - Cost-effectiveness is a major factor in businesses' decisions to use Chinese quick prototype manufacturers. In comparison to other countries, the cost of producing high-quality prototypes can be significantly reduced due to competitive pricing structures and lower labour expenses.

b. Speed and efficiency - Chinese producers are renowned for their speedy prototype delivery. They may drastically cut lead times with sophisticated technology and optimized workflows, enabling companies to quicken their product development cycles.

c. Technological expertise - The prototype industries in China have invested a lot to create rapid prototypes where the latest technologies have been used. This helps them to create an accurate model of your product.

d. Large-scale capabilities – The small and big production runs can be handled by a number of Chinese makers of quick prototypes. Scalability like this is quite helpful for businesses trying to go from developing prototypes to producing products on a large scale.

3. Challenges and considerations

a. Quality control - Although a lot of manufacturers provide excellent China product inspection services, there may be differences in quality. Businesses must perform extensive due diligence to make sure that prototypes fulfil their requirements, which includes assessing samples and creating precise quality control criteria.

b. Communication barriers - A typical problem with Chinese rapid prototype manufacturers is communication. People here are mostly not familiar with the English language, though technically, they may be quite sound. However, in order to develop a prototype, detailed communication is essential.

c. Intellectual property concerns - Another problem with China’s industries is that they don’t respect your intellectual property. Therefore, any foreign company that is interested in developing its prototype in China must register its trademark and design in China to protect its interest.

d. Shipping and logistics - There can always be a certain delay in the shipment when it is arriving from a foreign country, and China is not an exception. Therefore, businesses need to be proactive enough to address this issue.

4. The impact on global industries

Several international businesses have been significantly impacted by China's rise in fast prototyping:

a. Automotive industry - Within the automotive sector, rapid prototyping is a highly popular concept. Usually, this industry needs several parts that need to be developed and evaluated for their performance. The duration of the whole activity can be drastically reduced by rapid prototyping.

b. Aerospace industry - Rapid prototyping helps the aerospace sector by making it possible to test intricate parts and components affordably. Chinese producers of quick prototypes help aerospace businesses create cutting-edge materials and guarantee the dependability of vital parts.

c. Consumer electronics - In the field of consumer electronics too rapid prototyping plays a useful role as during the design stage, the manufacturers need to check several things, and by shortening the time, the companies can bring out their products in the market quickly.

d. Medical devices - Rapid prototyping makes it possible to create accurate and useful prototypes for testing and validation in the medical device sector. Chinese producers supply high-quality prototypes of surgical instruments, diagnostic tools, and other medical gadgets, which helps to progress medical technology.

How to choose the right rapid prototype manufacturers in China

To validate your design ideas practically, it is crucial that you select the right rapid prototype manufacturers to create your prototype. Not only will it save you time and money, but you can also finalize your product's design to your satisfaction.

1. Market research: You should start researching online to search for suitable prototype developers in China. Examine their social media presence, read internet reviews, and, above all, do a portfolio analysis.

2. Technological equipment: You are only as good as the technology you utilized to build your prototype. Verify that the rapid prototyping factory you select has access to cutting-edge software and equipment. In the long term, it will be worthwhile even though it could need some investment on your part. Additionally, keep in mind that the newest technology may not be the greatest option for your project.

There are several quick prototyping factories in China, so search for more! because the level of expertise varies among factories. While some people could be adept at creating plastic prototypes, others might be better at creating metal prototypes. Therefore, if you select the incorrect one, your project may be outsourced to a different manufacturing, which would ultimately cause a delay.

3. Customer reviews and experience - An excellent method to evaluate any service's quality is to read customer reviews. On the websites of the quick prototyping factories, you can obtain client reviews, but proceed with caution. The majority of factories create fictitious portfolios and pay people to write glowing testimonials about them.

4. Professional staff and customer support - The technology used by employees is just as vital as their professionalism. To address any questions you may have, the manufacturer ought to have a committed customer care team and a group of extremely knowledgeable and experienced experts. However, speaking with Chinese producers might be challenging because of the language barrier. And you are well aware that even a minor misunderstanding might result in serious issues.

5. Certifications and quality control - Ready to select a factory? But hold on! Before making your choice, confirm that the manufacturer adheres to strict quality control protocols and possesses all necessary certifications, such as ISO 9001 and ISO/TS 16949.

The majority of so-called rapid prototyping factories augmented their websites with fictitious credentials, taking advantage of their online presence.

Crucial factors to take into account when developing a prototype

There are a couple of other considerations in addition to the prototype development process. Let us examine them now.

1. Material selection - The final quality and price of your prototype will depend upon what material you have chosen for your prototype. Therefore, you need to select the material for your prototype very carefully. As the Chinese prototype developers have the right technology for rapid prototyping, they can quickly evaluate it by using several materials and help you to choose the right selection of material.

2. Manufacturing method - If you are totally new to the prototype industry, you may not know the pros and cons of various service providers in this field. Let us offer you a few tips here.

a. Additive manufacturing

One of the most popular prototype development technologies available in the market is known as additive manufacturing. Often this technology is also called 3D printing technology. By using this technology, you can create different layers of your prototype and obtain the right shape for your design.

The only con of this technique is that it has limitations in terms of size and material.

b. Subtractive manufacturing

Just the opposite of the above technology is subtractive manufacturing. In this technique a solid block of your chosen material is used to develop your prototype.

- Benefit – Wide variety of materials available.

- Drawback – Costly and time-consuming.

3. Finishing - Giving the prototype a final touch is crucial after it has been constructed. This covers plating, painting, and other finishing touches. The final shape and design will be based on this technique.

Conclusion

China has now become a major hub for rapid prototype suppliers. Therefore, businesses who want to search for rapid prototype manufacturers can find many reputed service providers to help them. However, it is also important to be aware of a few challenges as well. Through judicious selection and management of their manufacturing partners, companies can capitalize on the advantages of Chinese fast prototyping to propel innovation and realize development objectives.

China's position as a vital hub for advanced manufacturing and product development is expected to be further cemented as the global landscape continues to change and the significance of rapid prototyping expands.