In today's globalized economy, businesses are increasingly sourcing products and materials from suppliers around the world. As a result, effective global supplier management has become a critical element of success for companies looking to maintain a competitive edge. Building strong relationships with global suppliers is crucial for ensuring high-quality products, consistent delivery, and long-term collaboration. In this blog, we'll explore key strategies for building and nurturing strong relationships with global suppliers, with a focus on supplier management in procurement.

Understand the Importance of Supplier Relationships

Supplier relationships are often seen as transactional, but in reality, they form the foundation of a successful and sustainable supply chain. Strong supplier relationships foster trust, improve communication, and create a collaborative environment where both parties can thrive.

Global supplier management is more than just negotiating prices and delivery terms; it's about cultivating partnerships that benefit both your business and the suppliers. Effective supplier management in procurement can result in improved product quality, reduced lead times, cost savings, and innovation. Conversely, poor supplier relationships can lead to missed deadlines, subpar product quality, and increased operational costs.

Building strong relationships with global suppliers should be a top priority for any organization that depends on international sourcing. By investing time and effort into cultivating these relationships, businesses can ensure that their supply chain remains resilient, responsive, and efficient in the face of changing market conditions.

Communication is Key in Global Supplier Management

One of the most critical factors in building strong relationships with global suppliers is communication. Clear, consistent, and transparent communication lays the groundwork for mutual understanding and trust. In global supplier management, communication is especially important because of the geographical, cultural, and time zone differences that may exist between the buyer and the supplier. Open lines of communication foster mutual understanding, trust, and collaboration, all of which are essential for maintaining strong supplier relationships.

Here are some best practices for effective communication in supplier management:

1. Set Clear Expectations from the Start

One of the most important aspects of supplier management in procurement is establishing clear expectations right from the beginning. When managing global suppliers, misunderstandings can easily arise due to different business practices, time zones, and cultural differences. To prevent this, ensure that all parties understand the key requirements regarding pricing, delivery timelines, quality standards, and payment terms. Establish these expectations in a formal contract and reiterate them throughout your ongoing communication.

Additionally, both you and the supplier should understand the processes for handling issues such as quality concerns, delays, or changes in demand. This upfront clarity helps to avoid surprises and creates a framework for resolving problems efficiently when they arise.

2. Leverage Multiple Communication Channels

In the world of global supplier management, relying on just one mode of communication, such as email, can limit the effectiveness of your communication. Utilizing multiple communication channels can enhance clarity and responsiveness. While emails are great for formal communication, tools such as video calls, phone calls, and instant messaging platforms (like Slack or WhatsApp) are often better for real-time communication and addressing urgent matters.

Video conferences, for instance, can help build a more personal connection, allowing for face-to-face discussions regardless of the geographical distance. These interactions also help bridge cultural gaps, as body language and tone of voice can be more easily interpreted than in written form. When dealing with complex issues or negotiations, a combination of emails for documentation and video calls for discussions is the most effective approach.

3. Regular Check-ins and Feedback Loops

In global supplier management, regular check-ins and feedback loops are essential to keep the relationship strong and productive. Constant communication ensures that potential issues are identified early, and it creates opportunities to evaluate supplier performance. Scheduling regular meetings, whether weekly, monthly, or quarterly, to review performance, discuss upcoming needs, or address challenges helps maintain alignment between you and your suppliers.

During these meetings, it's important to provide both positive and constructive feedback. Recognizing and celebrating successes encourages suppliers to continue meeting expectations, while constructive feedback fosters improvement. Additionally, asking for feedback from your suppliers on your processes helps to identify areas where your organization can improve, leading to a more productive and collaborative relationship.

4. Be Culturally Sensitive and Adapt Communication Style

Effective communication in global supplier management isn't just about language – it's also about understanding cultural differences. Different regions of the world have varying communication styles, negotiation practices, and business etiquettes. For instance, while some cultures may value directness and efficiency, others may prioritize relationship-building and a more formal, polite approach.

Taking the time to understand these cultural nuances can significantly improve communication and reduce the risk of misinterpretations. Consider the supplier's country of origin when crafting messages or making calls, and be adaptable in your approach. For example, while in some cultures, emails may suffice for all communications, others may prefer face-to-face meetings or phone calls. By demonstrating cultural awareness, you show respect for your supplier's business practices, which can help strengthen the partnership over time.

5. Use Technology to Streamline Communication and Data Sharing

In today's digital age, using technology to streamline communication and data sharing is critical for effective supplier management. Supplier portals, cloud-based platforms, and Enterprise Resource Planning (ERP) systems allow both buyers and suppliers to access and share real-time data, such as order statuses, delivery updates, and inventory levels. These tools not only make communication faster but also reduce the risk of errors associated with manual data entry or outdated information.

A shared platform can also track key performance indicators (KPIs) related to quality, delivery timelines, and other metrics, making it easier to assess supplier performance and address any issues promptly. By utilizing such systems, you create a more efficient, transparent, and collaborative communication environment.

Foster Trust and Transparency

Trust is the foundation of any strong supplier relationship. It's essential for businesses to foster an environment of trust and transparency with their global suppliers. Trust encourages suppliers to go the extra mile to meet expectations and resolve issues when they arise. A relationship built on trust also encourages suppliers to share valuable insights that could lead to innovations or cost-saving measures.

To build trust and transparency in global supplier management:

1. Be Honest and Transparent

Always share relevant information with your suppliers, including any changes in demand, product specifications, or market conditions. Transparency in forecasting and planning allows suppliers to adjust their production schedules and manage their own resources more effectively.

2. Handle Disputes Professionally

Disagreements are bound to occur in any business relationship. However, how you handle them can make a significant difference. Instead of blaming the supplier or engaging in adversarial tactics, approach the situation calmly and professionally. Collaborate with your supplier to find a mutually beneficial solution, keeping the long-term relationship in mind.

3. Maintain Consistent Performance

Trust is built over time, and it's essential to maintain consistent performance. Honor your commitments, whether they involve payment terms, delivery schedules, or quality standards. When your suppliers see that you are reliable, they will be more likely to reciprocate.

Invest in Long-Term Partnerships

While short-term transactional relationships may provide quick results, long-term partnerships offer greater benefits over time. Investing in long-term relationships with global suppliers provides a range of advantages, including better pricing, improved product quality, and the ability to leverage suppliers for innovation and problem-solving.

Here are some strategies for building long-term partnerships in supplier management:

1. Foster Open and Transparent Communication

Clear and open communication is a foundational element of any successful partnership. Regular, proactive communication ensures that both parties are aligned in terms of expectations, goals, and challenges. Setting up regular check-ins and performance reviews with your suppliers allows you to address potential issues early, discuss improvements, and stay aligned on objectives. By being transparent about changes in demand, quality requirements, or other concerns, you create a collaborative environment where both sides can work together to find solutions. Trust grows when communication is open and honest, allowing for more effective problem-solving and reducing the risk of misunderstandings.

2. Collaborate on Innovation and Process Improvement

Building a long-term partnership goes beyond just meeting immediate needs; it involves working together to drive mutual growth and innovation. Collaborating with suppliers on product development, process improvements, and cost-saving initiatives can strengthen the partnership and provide a competitive advantage. Suppliers often have unique insights into their manufacturing processes and industry trends that can lead to improved product designs or efficiencies. By involving your suppliers in these discussions, you create an environment of shared success, where both parties benefit from ongoing improvements. This not only improves the quality and performance of the products but also fosters a culture of continuous improvement.

3. Align on Values and Sustainability Goals

In today's market, sustainability and ethical practices are increasingly important to both consumers and businesses. Aligning on values, such as environmental responsibility and social governance, strengthens long-term relationships with suppliers. When both parties share a commitment to sustainability, it creates a foundation for collaboration that goes beyond short-term goals. Ensure that your suppliers adhere to ethical labor practices, environmental regulations, and other sustainability standards that align with your company's values. This alignment not only improves the reputation of both companies but also helps build a future-proof partnership that can adapt to changing market expectations.

Regularly Review and Evaluate Supplier Performance

To ensure that supplier relationships remain strong, it's important to regularly review and evaluate supplier performance. Supplier management in procurement involves continuous monitoring and assessment to identify opportunities for improvement or areas where the supplier may be falling short. Regular evaluations help keep both parties on track and ensure that the relationship continues to meet expectations.

Here are some key metrics to evaluate supplier performance:

1. Quality of Goods or Services

Track the quality of products delivered by the supplier, including defect rates, returns, and customer complaints. Maintaining high-quality standards is essential for a successful supplier relationship.

2. Delivery Timeliness

Assess how well the supplier adheres to delivery schedules. Timely delivery is critical to maintaining an efficient supply chain, and consistent delays should be addressed promptly.

3. Cost Competitiveness

Regularly evaluate pricing to ensure that you are getting competitive rates for the quality of products provided. If the supplier is charging more than others for similar goods, it may be time to renegotiate or explore alternative suppliers.

4. Innovation and Value-Added Services

Look for suppliers who offer more than just basic goods or services. Suppliers who can contribute to product development, suggest process improvements, or help reduce costs add significant value to the relationship.

5. Sustainability and Compliance

Evaluate your supplier's commitment to sustainability, ethical practices, and compliance with relevant regulations. This is particularly important as companies face increasing pressure to meet environmental, social, and governance (ESG) standards.

Leverage Technology for Efficient Supplier Management

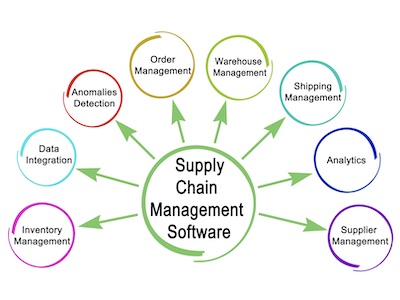

In today's digital age, technology plays a significant role in streamlining global supplier management. Leveraging software tools and platforms for supplier relationship management (SRM) and procurement can greatly enhance efficiency, communication, and transparency.

Here are some technology solutions to consider for managing global supplier relationships:

1. Supplier Portals

A supplier portal allows suppliers to access essential information about their orders, shipments, and payments. It can also be used to communicate updates, submit invoices, and track performance metrics. These portals facilitate smoother communication and reduce the administrative burden on both sides.

2. Data Analytics and AI

Data analytics and artificial intelligence can provide insights into supplier performance, demand forecasting, and supply chain optimization. By using predictive analytics, you can anticipate potential issues and make data-driven decisions that improve your relationships with suppliers.

3. Enterprise Resource Planning (ERP) Systems

An ERP system can help integrate supplier management processes with other parts of the business, such as finance, inventory, and production. This integration ensures that suppliers have real-time access to data, leading to better coordination and fewer errors.

4. Cloud-Based Collaboration Tools

Tools like Slack, Microsoft Teams, or Trello can enhance communication and collaboration between your business and global suppliers. These platforms allow for real-time discussions, project management, and document sharing, keeping everyone aligned and informed.

Conclusion

Building strong relationships with global suppliers is crucial for achieving long-term success in today's competitive marketplace. By focusing on clear communication, trust, transparency, and mutual collaboration, companies can foster supplier relationships that are both productive and sustainable. Effective supplier management in procurement is about more than simply meeting deadlines and costs; it's about creating lasting partnerships that drive value, innovation, and growth. Investing in these relationships allows businesses to build resilient supply chains, improve operational efficiency, and remain competitive in an ever-evolving global market.