When sourcing prototypes, China remains a top choice for companies across the globe. Chinese prototype manufacturers offer high-quality production at competitive rates, making it an attractive destination for companies that want to bring innovative ideas to life without overspending. However, navigating the prototype manufacturing industry in China comes with its challenges. This guide will walk you through critical steps to safely and effectively source prototypes from Chinese manufacturers, helping you avoid common pitfalls and ensuring a smooth development process.

Why Choose Chinese Prototype Manufacturers?

Choosing the right prototype manufacturer is a pivotal decision in product development, and for many companies around the world, China has become the go-to destination for prototyping needs. Chinese prototype manufacturers offer an enticing blend of advanced manufacturing technology, cost-efficiency, and a vast network of specialized factories. In this article, we'll discuss the main reasons why Chinese prototype manufacturers are favored globally and how they can benefit your product development process.

1. Cost Efficiency Without Compromising Quality

One of the primary advantages of working with Chinese prototype manufacturers is the cost savings. China's well-established manufacturing ecosystem allows companies to access high-quality services at significantly lower prices compared to many Western countries. Here's why:

Lower Labor Costs: Labor costs in China remain lower than in many parts of the world, allowing manufacturers to offer competitive pricing without compromising product quality.

Efficient Supply Chains: China's extensive supply chains mean that materials, components, and other resources are readily available. This results in faster production times and reduced costs, benefiting companies with tight budgets or timelines.

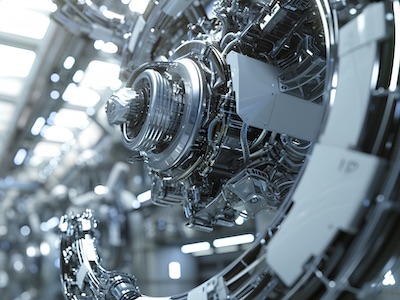

Advanced Machinery and Skilled Workforce: Over the years, Chinese manufacturers have heavily invested in advanced machinery and trained a highly skilled workforce, enabling them to handle complex prototyping requirements at competitive rates. From CNC machining and injection molding to 3D printing, manufacturers in China can accommodate a range of prototyping needs across different industries.

This combination of cost-effective labor, efficient supply chains, and advanced technology has enabled China to become a leader in prototyping services, providing companies with a unique balance of affordability and quality.

2. Broad Range of Prototyping Capabilities

Chinese prototype manufacturers offer an impressive variety of prototyping techniques, from traditional methods to the latest in additive manufacturing. This broad range of capabilities makes it easier for companies to find a manufacturer that matches their specific product requirements.

Versatility in Materials and Methods: Whether you need metal, plastic, glass, or specialized materials, Chinese manufacturers can typically provide the resources to support your project. Techniques like CNC machining, injection molding, sheet metal fabrication, and 3D printing are all readily available and can be tailored to meet diverse product specifications.

Specialized Expertise Across Industries: Chinese manufacturers serve a vast array of industries, including automotive, electronics, medical devices, consumer goods, and more. With this experience, they bring a wealth of knowledge and expertise to support various project requirements, from small batches to large-scale production.

Rapid Prototyping and Fast Turnaround: The infrastructure in China allows for fast prototype production, enabling companies to iterate quickly and bring products to market faster. This is particularly advantageous in competitive markets where speed is critical.

3. Strong Support for Scaling from Prototype to Production

Chinese manufacturers don't just excel in prototyping; they're also well-equipped to scale to full production when needed. Many companies choose China for prototyping with the intention of moving to mass production, and working with a Chinese manufacturer from the start can simplify this transition.

Seamless Transition to Mass Production: Starting with a Chinese prototype manufacturer who also offers production services means you can transition to large-scale manufacturing without switching suppliers. This not only saves time and resources but also maintains consistency in product quality.

Adaptability for Product Development: Chinese manufacturers are accustomed to accommodating changes, making it easier for companies to refine their prototypes and adjust design details without long delays. This flexibility can be essential when refining a product for its final market-ready form.

Key Steps for Safely Sourcing Prototypes in China

Sourcing from Chinese prototype manufacturers requires careful planning and attention to detail to avoid quality issues, communication barriers, and logistical challenges. Here's a step-by-step guide to help you safely source prototypes in China, ensuring a smooth and successful experience.

1. Research and Identify Reliable Chinese Prototype Manufacturers

Finding a trustworthy manufacturer is critical when getting a prototype made in China. Here are a few effective strategies for identifying reliable partners:

Industry Research: Begin by researching reputable manufacturers in the industry, prioritizing those that specialize in your product type. Websites like Alibaba, Made-in-China, and Global Sources provide access to supplier profiles, allowing you to view their certifications, product catalogs, and customer reviews.

Check Certifications and Credentials: Ensure that potential manufacturers have the required certifications, such as ISO9001 for quality management, CE marking, or RoHS compliance, depending on your industry. These certifications indicate that the manufacturer adheres to global standards.

Ask for References and Past Work Samples: Reliable manufacturers should be able to share samples of past prototypes or connect you with previous clients. Viewing samples and understanding their experience with similar projects can give you insights into their capabilities and attention to detail.

Consider Hiring a Reliable Sourcing Company: Sourcing agents can bridge the gap between you and the manufacturer. They often have established relationships with local suppliers, are familiar with the language, and can help verify a manufacturer's legitimacy, potentially saving you time and reducing risks.

2. Clear and Detailed Communication

When outsourcing overseas, effective communication is crucial. Language barriers, cultural differences, and time zones can all impact the clarity of your project's requirements. To prevent misunderstandings, follow these steps:

Develop Detailed Product Specifications: Clearly outline every detail of your product, from dimensions and materials to finishes and tolerances. Use visual aids, such as CAD drawings or 3D renderings, to illustrate your design more precisely.

Specify Quality Standards and Testing Procedures: Set clear expectations regarding the quality standards and testing methods you require. For instance, if your product has to pass certain durability or safety tests, make sure the manufacturer understands and can meet these requirements.

Choose a Manufacturer with Good Communication Practices: Some Chinese manufacturers may have dedicated English-speaking staff, which can significantly improve communication. Consider this when choosing your manufacturer to avoid language-related misunderstandings.

Conduct Site Visits and Quality Audits

While the internet offers convenience, nothing beats the insight you gain from an in-person visit. Conducting a factory visit or commissioning a third-party factory audit services can help you verify a manufacturer's production capabilities and quality control processes.

1. Why Site Visits are Essential When Working with Chinese Prototype Manufacturers

Conducting an on-site visit is one of the most reliable ways to assess a potential Chinese prototype manufacturer. While online profiles, certifications, and product images provide insight, they cannot fully reveal the manufacturer's capabilities, work environment, and quality standards.

Direct Observation of Facilities and Equipment: Seeing the factory in person allows you to confirm that they have the necessary machinery and tools for your project. During a site visit, you can observe the conditions of the equipment, verify the types of manufacturing processes they can handle, and assess whether they have the capacity for your required prototype specifications.

Evaluate Staff Expertise and Production Processes: During your visit, you can interact with the management team and technicians to gauge their knowledge, skills, and familiarity with your industry. Observing production processes firsthand provides valuable insights into the team's efficiency, quality control practices, and adherence to safety protocols.

Understand the Company Culture and Work Environment: A site visit offers a glimpse into the factory's organizational structure, cleanliness, and overall work environment. Companies with organized, well-maintained facilities and clear processes tend to have higher production standards and a stronger commitment to quality.

While a site visit can incur additional travel expenses, the information you gain can prevent costly mistakes and ensure you're partnering with a reliable and capable manufacturer.

2. Conducting Quality Audits for Chinese Prototype Manufacturers

Quality audits are crucial to verify that a manufacturer's processes meet your quality and regulatory standards. Even if a site visit is not feasible, a third-party quality audit can provide you with a detailed evaluation of the manufacturer's capabilities and adherence to industry standards.

Partner with a Trusted Third-Party Auditor: Third-party agencies like SGS, Bureau Veritas, and Intertek offer quality inspection services and have local branches in China. These agencies have experienced inspectors who are familiar with Chinese manufacturing practices, providing you with an objective assessment of the manufacturer's quality management systems, production capacity, and operational reliability.

Review Quality Control Documentation: Quality audits involve reviewing a manufacturer's internal quality control documentation, such as process records, inspection logs, and certifications like ISO 9001. This documentation reveals how the manufacturer tracks quality across different stages of production and handles any defects that arise.

Evaluate Compliance with Industry Standards: Depending on your industry, compliance with specific regulatory standards may be required. For example, medical devices, electronics, and automotive parts must meet stringent quality and safety standards. A third-party audit can confirm whether the manufacturer complies with these regulations, reducing the risk of issues during production or export.

Conducting a thorough quality audit is a proactive step that helps verify whether the manufacturer's processes are aligned with your quality expectations. By obtaining an objective assessment, you minimize the risk of receiving prototypes that don't meet your specifications.

3. Final Inspections and Testing: Ensuring Quality Before Shipment

After completing site visits and quality audits, it's important to ensure that each prototype batch meets the required standards before shipment. A pre-shipment inspection or testing phase acts as the final safeguard in the sourcing process.

Conduct Pre-Shipment Inspections: A pre-shipment inspection involves evaluating a sample from the finished batch of prototypes to check for defects, dimensional accuracy, material quality, and overall functionality. This inspection, often conducted by a third-party inspector, helps catch any issues before the prototypes are shipped to you. Pre-shipment inspections are particularly valuable for complex prototypes where minor flaws can have a significant impact.

Request Testing Certificates and Reports: For prototypes requiring compliance with specific safety or industry standards, request testing certificates and reports before the products leave the manufacturer. Testing should be performed by accredited labs to ensure reliability. Verifying these certificates provides assurance that the prototypes will meet regulatory standards upon arrival, particularly for products in highly regulated industries.

Establish Clear Guidelines for Corrective Actions: If the inspection or testing reveals any defects or deviations from your specifications, establish a clear protocol for corrective actions. This could include requesting a replacement batch, additional quality inspections, or rework at the manufacturer's expense. Establishing these guidelines ahead of time ensures a smooth process in the event of any quality discrepancies.

By implementing pre-shipment inspections and obtaining testing certificates, you ensure that the prototypes you receive meet your quality standards, reducing the risk of delays and rework.

Understand Contract Terms and Intellectual Property Protection

One of the primary concerns companies have when outsourcing prototypes is protecting their intellectual property (IP). When working with Chinese manufacturers, ensure you have strong contractual terms in place to protect your designs.

Sign Non-Disclosure Agreements (NDAs): An NDA is essential to safeguarding your proprietary information. It limits the manufacturer's ability to share or use your designs without permission.

Use Non-Compete and Non-Use Clauses: These clauses prevent the manufacturer from producing or selling your design to other customers or using it for purposes outside of your contract.

Register Your IP in China: Intellectual property laws vary by country, and registering your patent or design in China provides you with a stronger legal foothold should any infringement occur.

Set Clear Payment Terms and Delivery Milestones: Outline payment terms that are tied to specific project milestones, such as a portion upon prototype completion and another upon successful quality inspection. This structure helps maintain control over the production timeline and quality.

Arrange Ongoing Quality Control and Final Inspections

Ensuring consistent quality throughout the production process is vital, especially for complex prototypes. Ongoing quality control checks help detect issues early, saving time and money.

Use In-Process Quality Control (IPQC): Regular quality checks during different production stages can help catch defects early. Manufacturers that offer in-process quality control demonstrate a commitment to maintaining high standards throughout the manufacturing process.

Plan for Final Pre-Shipment Inspections: Before finalizing the shipment, conduct a comprehensive inspection to ensure the prototype meets your specifications. This may involve a third-party inspection agency or, if feasible, a visit by a sourcing agent or representative.

Request Testing Certificates: If your prototype must comply with specific industry standards, request the relevant certificates or testing reports before shipping. Having these documents in hand is essential for ensuring that the product meets all regulatory requirements in your target market.

Conclusion

The process of sourcing prototypes from Chinese prototype manufacturers can yield significant rewards in cost savings and production efficiency. However, a thoughtful and strategic approach is essential to avoid common pitfalls. By selecting a reputable manufacturer, prioritizing clear communication, verifying production quality through audits, and establishing comprehensive legal protections, you can secure a successful partnership that brings your innovative ideas to life.

Remember: Taking the time to properly vet your supplier and establish a strong foundation will lead to a smoother manufacturing journey, ultimately saving you time and money. For more complex projects, working with a reliable sourcing company or agent can further enhance your chances of success by providing on-the-ground support and expertise. With the right safeguards, you can confidently engage Chinese prototype manufacturers and turn your vision into a tangible, high-quality prototype.